Laser Welding

Technical Features

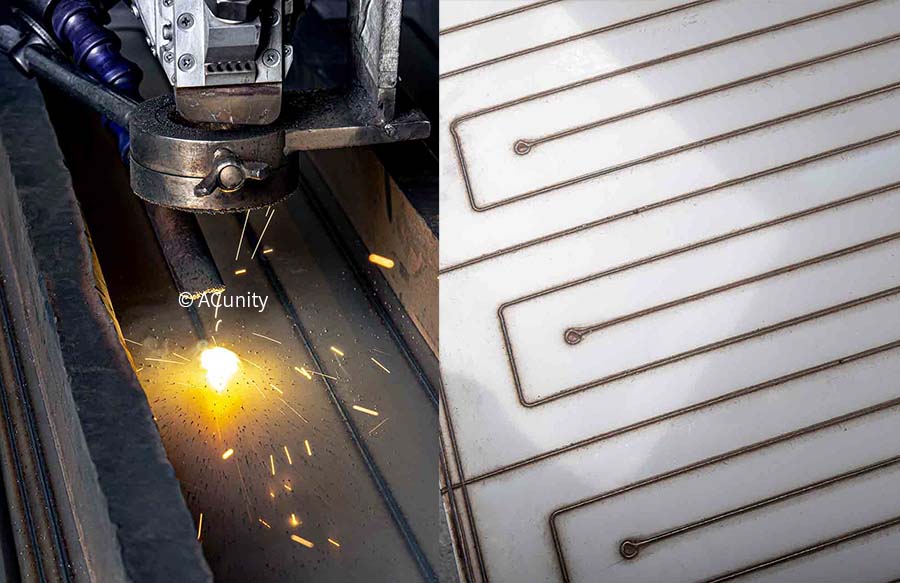

Laser welding can be used in continuous, pulse energy output, according to energy density, laser welding into the laser heat conduction welding and laser deep welding two modes. Typically, the laser energy density is less than 10^4~10^5 W/cm² of heat conduction welding, the laser incident energy density is low, the workpiece absorption of energy is insufficient to make the metal vaporization, only melting occurs, then the metal melted by the laser radiation absorption and heat conduction is carried out. Since there is no steam pressure, the heat flux when the melt depth is generally shallower. The laser energy density is greater than 10^5~10^7 W/cm2 for deep penetration welding, the energy density level of the laser in a very short period of time so that the heating area of the metal vaporization, resulting in the liquid melt pool formed in a small hole, called the spoon holes. The beam can be directly into the keyhole inside, through the keyhole of heat transfer, obtain a greater Weld depth.

The characteristics of laser welding compared to traditional arc welding methods are:

![]() High energy density, resulting in a large weld depth-to-width ratio

High energy density, resulting in a large weld depth-to-width ratio

![]() Minimal welding deformation

Minimal welding deformation

![]() High welding speed and efficiency

High welding speed and efficiency

![]() Precisely adjustable energy

Precisely adjustable energy

![]() Compatible with a wide range of materials, including dissimilar materials

Compatible with a wide range of materials, including dissimilar materials

![]() The beam can be customized as needed

The beam can be customized as needed

Technical Advantages

![]() Laser-arc hybrid welding: Efficient welding for medium to thick plates

Laser-arc hybrid welding: Efficient welding for medium to thick plates

![]() Swing beam welding: Suitable for difficult-to-weld and dissimilar materials

Swing beam welding: Suitable for difficult-to-weld and dissimilar materials

![]() Low vacuum laser welding: high-quality, high efficient welding

Low vacuum laser welding: high-quality, high efficient welding

![]() Multi-weld component low distortion welding: Automatic recognition and planning for complex welding paths

Multi-weld component low distortion welding: Automatic recognition and planning for complex welding paths

![]() Process monitoring: Real-time monitoring of melt pool morphology, temperature, and reflected light with automatic seam tracking

Process monitoring: Real-time monitoring of melt pool morphology, temperature, and reflected light with automatic seam tracking

![]() Material: Steel, nickel, titanium, aluminum, dissimilar materials, etc.

Material: Steel, nickel, titanium, aluminum, dissimilar materials, etc.

Technology Background

Laser welding technology, characterized by low heat input, minimal deformation, and high efficiency, has been widely applied in modern industrial production across various sectors, including automotive, rail transport, energy, aerospace, steel, and electronics. The advent of new high-power, high-brightness lasers and the rapid development of beam-shaping technology have led to increasingly diverse advancements in laser welding technology.