EHLA-Flexi

The tiresome issue of component wear is now history! We offer you a comprehensive repair service package based on the most advanced robot technology, flexible linear units and innovative laser-based process. This enables us to carry out both 2D surface repairs and precise 3D additive repairs to meet all requirements. Precise control by the robot ensures high and efficient repair quality. Our robot linear units offer an additional axis, which allows workspaces to be significantly enlarged and thus adapted to any component size. Completely without manual intervention, our machines minimize human error and guarantee fast, efficient and first-class repairs.

-

![Load capacity 5000 kg]()

Load capacity 5000 kg

Maximum of 5000 kg partsfor EHLA

-

![Inner/outer wall cladding processing]()

Inner/outer wall cladding processing

Modular design, high practicality, easy conversion of machine parts or laser optical components to meet different process requirements

-

![Efficient powder feeding nozzle]()

Efficient powder feeding nozzle

High-precision convergence Powder,flow Full-channel water-cooled design

-

![Energy efficiency]()

Energy efficiency

The processing process has low energy consumption, greatly reduces costs, and has little impact on the environment

-

![Powerful operation software]()

Powerful operation software

Suitable for complex process processing, with a convenient and fast user interface.

-

![Robot flexibility]()

Robot flexibility

Surface coating and versatile additive manufacturing processes - our EHLA Flexi masters both.

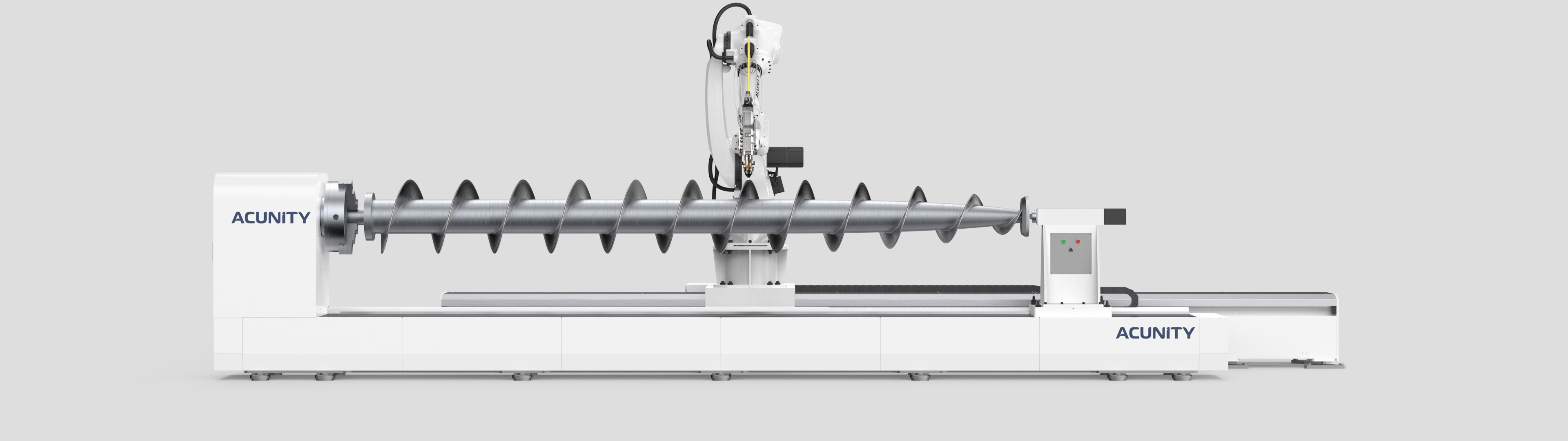

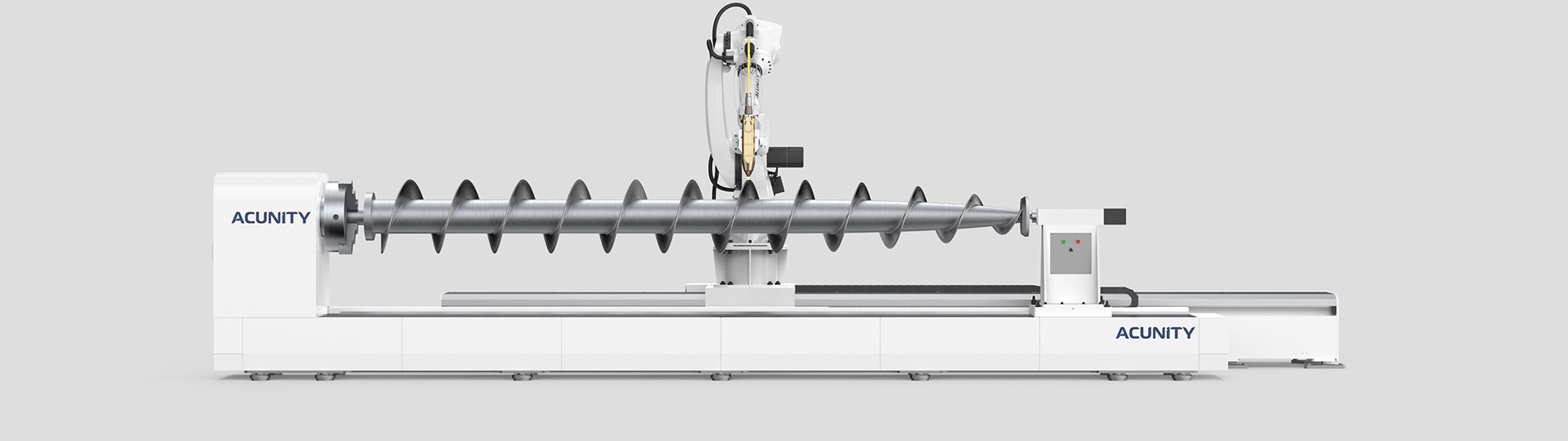

P-RLC-5000

The laser processing equipment equipped with the robot has an almost unrestricted working area. Therefore, the processing can be flexibly adjusted according to the geometry and size of the workpiece.

Technical Data

-

Equipment model

P-RLC-5000

-

Workmanship

Internal/external coating fusion

-

Load capacity (maximum)

3000 kilograms

-

Maximum component length

5000 mm

-

Component diameter

Maximum 1000 mm

-

Laser

3-12 kW

-

Speed

Maximum 100 rpm

-

Nozzle angle

90°

-

Single layer thickness

50-1000µm

-

Cladding speed

0.6-1.6 m²/h

-

Monitoring system

Optional

-

Distance control

Optional