Industrial Applications

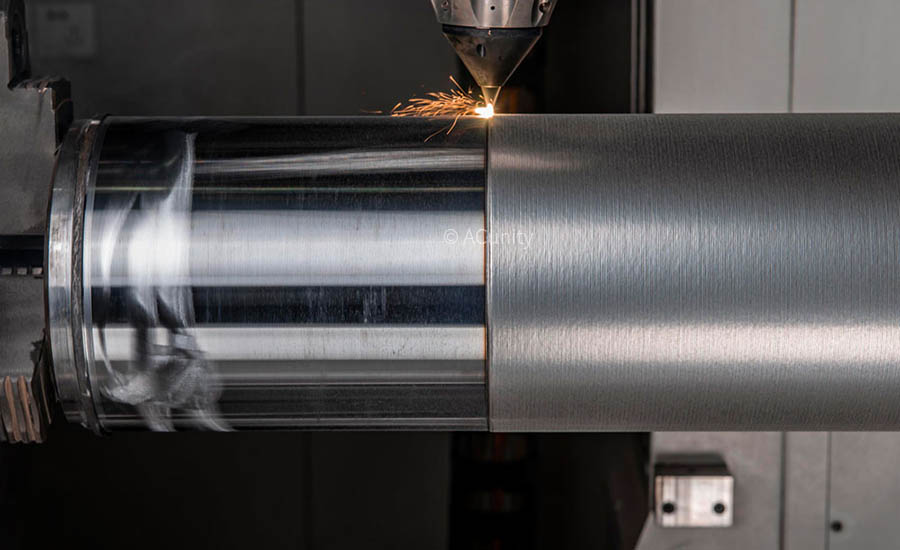

The surface processing technology of important shaft components such as rollers and hydraulic supports, which are subjected to force, is still mostly used for wear and corrosion protection through electroplating, thermal spraying, or traditional laser cladding. Traditional surface processing techniques often have the following obvious drawbacks: using environmentally harmful chemicals, higher processing costs, lower interlayer adhesion, and so on. ACUNITY-EHLA, as a new-generation surface processing system, provides corrosion and wear-resistant material surface solutions for axisymmetric load-bearing structural components. It is mature, efficient, and environmentally friendly and is a perfect replacement for traditional processes.

Coal Industry

The working environment of coal machinery is complex and harsh, with long equipment operation time and heavy load, especially in humid underground environments, various harmful gases, dust particles, and other problems, which can easily cause corrosion and wear on mechanical equipment, greatly shortening its service life. The main forms of failure of these devices are wear, corrosion, scratches, etc., such as wear failure of cutting teeth, scraper conveyor grooves, gears, shafts and other components, corrosion failure of hydraulic support columns, oil cylinders, piston rods, etc. The pillars, oil cylinders, and other components of hydraulic supports are currently mostly prepared and repaired using electroplating methods for surface corrosion resistance layers. Due to the low bonding strength of the coatings and the short service life, they often need to be transported from underground for disassembly and maintenance, resulting in a large installation workload and long installation cycle.

Nowadays, intelligent technology is gradually being promoted in the coal mining industry, achieving unmanned operation underground and the application of high-quality and long-term service products is an inevitable trend, which puts higher requirements on the performance and service cycle of hydraulic support columns. Applying high-efficiency, high-quality, and low-cost green manufacturing technologies can enhance market competitiveness and create long-term value growth for enterprises.

Oil Drilling

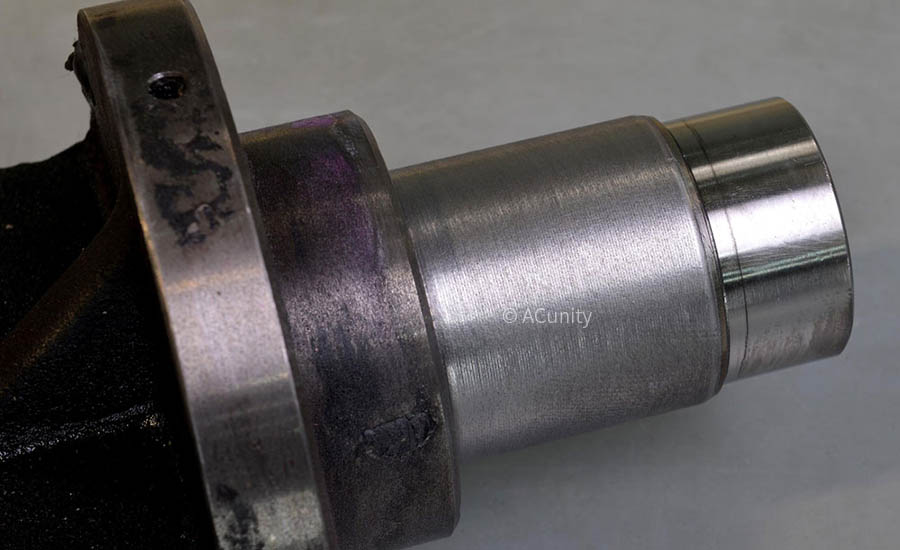

Due to the harsh working conditions of downhole oil operations, many downhole tools are subjected to long-term loads and used under corrosive and abrasive working conditions, resulting in premature failure and damage, and thus shortening their life, for example, prominent rotor journals, wheels, sleeves, shaft tiles, oil drill collars, Etc. However, these parts are often costly, involving many components, complex shapes, and significant differences in working conditions. Therefore, stopping production for maintenance and updating details increases material costs and affects oilfield production, and brings losses in many aspects. Therefore, most oil drilling companies will choose laser cladding technology to prepare and repair the hard coating of large parts in the wear area without preheating. The subsequent processing volume is small, shortening the repair cycle, improving the surface hardness, corrosion resistance, and wear resistance of the workpiece, and significantly improving the service life of the parts.

Ocean Engineering/Ship

Due to long years of work in rivers and marine environments, many parts in mechanical equipment such as ships of drilling platforms and large ship cranes will be corroded and worn and need to be protected and repaired. For the preparation of wear and corrosion-resistant coatings on the surface of shaft parts, efficient surface processing technology is required; while some power equipment local wear and tears, such as iron chips and impurities in the lubricating oil system, the impact of low oil temperature or oil pressure during the start-up process of the unit, easy to cause the shaft tile and shaft diameter wear, the need for the local area of the melting and repair, suitable for the use of better flexibility of the robot automatic repair method.

For the problems of wear and corrosion of marine machinery parts, laser cladding repair and remanufacturing technology can meet the application needs of the above situation at the same time and has been widely used in a variety of products such as marine diesel engines, marine gas turbines, steam turbines, propellers, and ship hulls.

Construction Machinery

Construction machinery, including lifting machinery, earthmoving machinery, transportation machinery, concrete machinery, railroad maintenance machinery, and many other types, in critical, parts are required to wear-resistant coating preparation to improve service life, in coastal or wet environment service also need to consider the corrosion resistance of the equipment. A long-term harsh working environment is straightforward to cause damage to various types of equipment components, such as peeling, peeling, cracking, impact, corrosion, wear, and so on. Therefore, maintenance costs remain high when engineering machinery and equipment and its members need regular maintenance or repair, as well as maintenance workload.

At present, most of the engineering machinery and equipment parts are prepared by electroplating, thermal spraying, and other methods for surface coating, which have limitations such as pollution, low bond strength, and short service life to varying degrees. Efficient, high-performance surface engineering technology, remanufacturing repair technology, and connection technology have excellent construction machinery application prospects.

Agricultural Machinery

During the cutting process of agricultural machinery equipment, the cutting tools must withstand impact and vibration loads, as well as strong friction between the workpiece and chips, resulting in frequent wear, rolling, chipping, or breakage of steel cutting tools during use, which affects machining accuracy and production efficiency, shortens the service life of the tools, and increases production costs.

Water Conservancy Equipment

Higher hardness impurities or particles in the process of machine operation will produce wear and tear on the spiral, the wear and tear of the spiral will not only affect the normal operation of the equipment, but also accelerate the wear and tear of other parts, resulting in a decline in the overall performance of the equipment, or even early scrapping. Through laser cladding technology, the spiral surface can be partially repaired to fill the defects and cracks, prolonging the service life, reducing the frequency of maintenance and replacement, and lowering the operating costs.

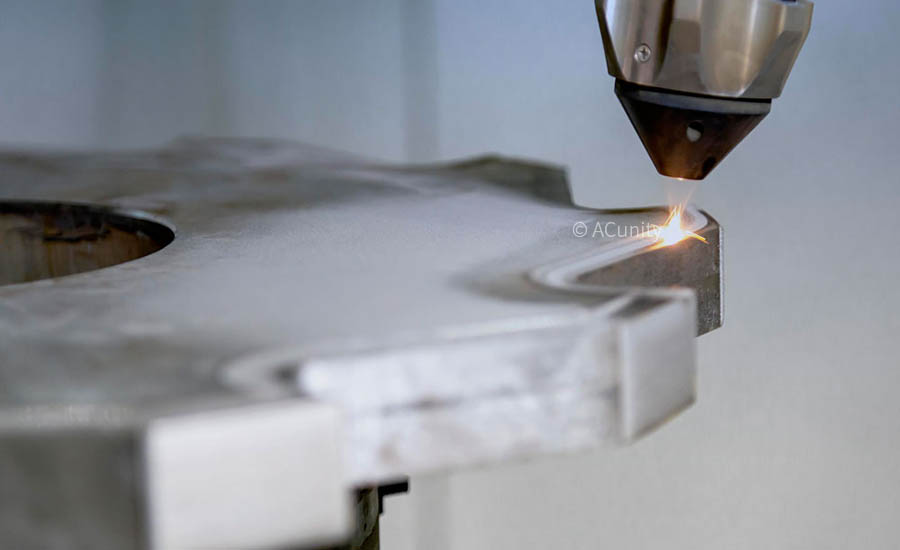

Mold Maintenance/Manufacturing

Moldsare used in a wide range of applications, and the vast majority of partsrequire molding. The service life of the mold depends on its anti-wear andanti-mechanical damage ability. Once excessive wear or mechanical damage, theshape-damaged parts are challenging to repair and can only be purchased orcustomized with new molds. The mold manufacturing process is complicated, withthe long production cycle and the high processing cost. Therefore, the repairand reuse of failed molds undoubtedly have significant economic benefits. Thereare many methods to repair molds, such as EDM, argon arc welding repair, laseroverlay welding, electric brush plating, Etc. Laser cladding technology formold repair is a unique advantage; the powder material is flexible andadjustable to meet different service performance requirements, can preparedifferent kinds of wear-resistant, high-temperature, scour-resistant coatings,and even gradient coatings, coating materials can be cobalt-based,nickel-based, and ceramic composite materials. Compared with traditional arcwelding technology, the heat input of laser cladding is small, the thermalimpact on the substrate is small, and the residual stress in the repair area ismore minor; and the precision is high, which can realize the precision repairof tiny defects in high-grade molds.

Paper/ Printing

The printing guide roller includes a guide roller body, and the two sections of the guide roller body are respectively equipped with roller pillows and shafts. Many printing factories experience mechanical wear and chemical corrosion on their guide rollers due to prolonged operation, which in turn affects production efficiency and quality. The most direct method for collecting worn and corroded printing guide rollers is to replace the components, but the cost will increase.

Steel / Metallurgy

Steel and metallurgical plant components in the production line service environment for most high temperature, high variable load, hot and cold cycling, corrosion, wear and fatigue conditions. Some cast iron parts are prone to corrosion and model, and need to be replaced and maintained regularly in the use process. Especially in the production and processing of high-end automotive steel plates, the surface quality of rolls, transfer rolls and other parts is very demanding. For this kind of parts with high usage and high maintenance frequency, how to further effectively improve the service life and reduce the maintenance cost is crucial to the development of the industry. The current surface protection layer of steel and metallurgical equipment parts is mainly prepared by electroplating, thermal spraying, arc welding and other methods. The application of laser cladding technology can more effectively improve the service life of the parts coating, reduce maintenance links, both in terms of coating thickness, coating performance regulation and other aspects that have greater flexibility.