EHLA

Convenient Process, Economical

and Pollution-Free

EHLA technology is used to improve the wear resistance, corrosion resistance, high-temperature resistance, and oxidation resistance of the surface of parts, thus achieving the goal of surface modification or repair and meeting the requirements for specific properties of the material surface.In the conventional laser cladding process, laser energy is used to melt the base material to form a molten pool into which the powder is injected and then melted and solidified to form a protective coating.

EHLA technology essentially changes the melting position of the powder so that the powder intersects the laser right above the workpiece and is then uniformly coated on the workpiece surface. Due to the low heat input, the technology can be used for surface coating of heat-sensitive materials, thin-walled and small components. In addition, it can be used to prepare coatings on entirely new material combinations such as aluminum-based, titanium-based, or cast iron materials.

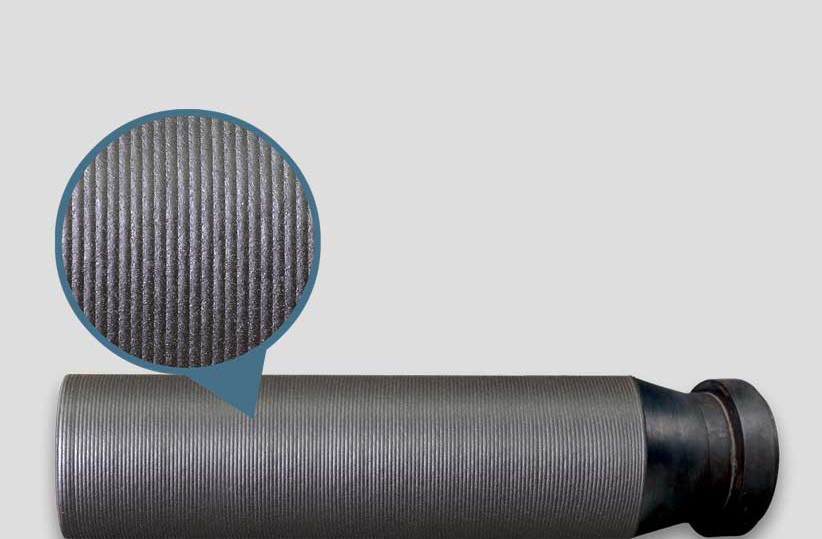

A New Solution for Surface Coating Preparation of Axis Components

Innovation in Process Control

Powder Particles Directly Melt in a Laser Beam

EHLA is a further development of conventional laser metal deposition. This technology owes its breakthrough largely to an innovation in process control that enables much higher coating speeds. The new approach is to completely liquefy the powder particles before they hit the surface of the workpiece.

EHLA is a synchronized powder feed process in which the relative position of the powder's focal plane and that of the laser are adjusted so that the cladding powder intersects and melts the laser beam above the substrate and is then evenly applied to its surface. After rapid solidification, the cladding layer has a very thin coating and is metallurgically bonded to the substrate.

Advantages Compared toConventional Laser Cladding

The main difference from conventional laser cladding is the change in the melting position of the powder. Using extreme high-speed laser metal deposition technology - EHLA, the melted powder material falls on the surface of the substrate instead of solid powder particles, resulting in a significant increase in cladding speed. For traditional laser cladding, a linear speed of 0.5 to 2.0 m/min is usually achieved, while EHLA is 20 to 200 m/min, which is equivalent to an increase of 40 to 100 times. Therefore, this technology can be used to coat large-area parts.

Melting Position of the Powder

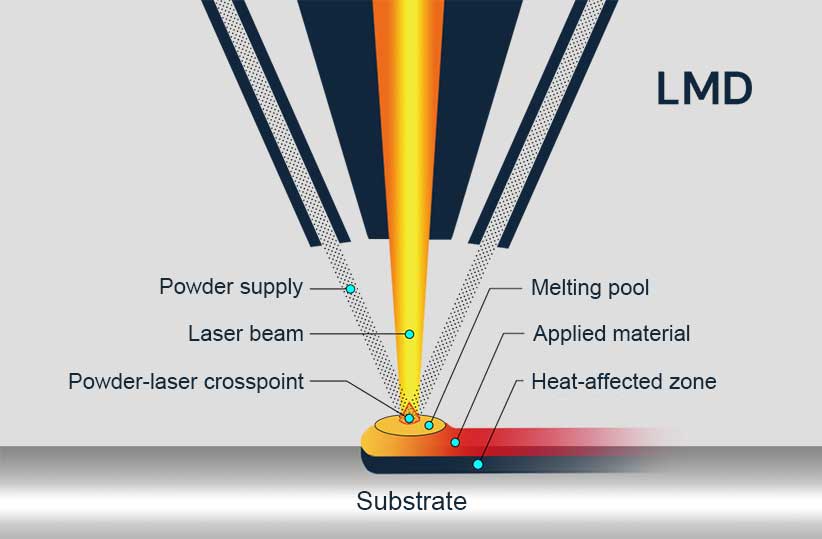

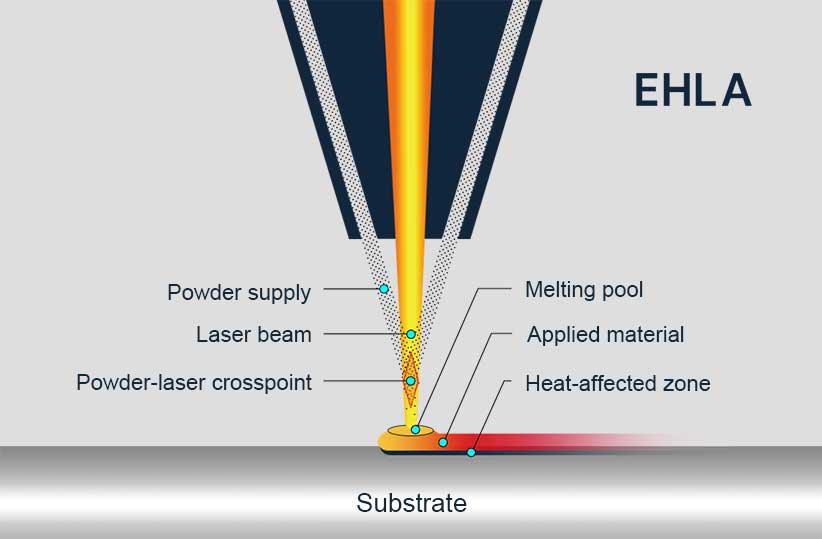

A process comparison between conventional laser metal deposition and EHLA

Inlaser metal deposition (LMD), the laser beam heats the substrate and createsthe molten pool into which the powder is injected. This melts, combines withthe base material and solidifies to form a protective layer. The substrateabsorbs most of the energy.

In extrem high-speed laser metal deposition (EHLA), the melting position of the powder is changed so that it crosses the laser beam over the substrate and is then applied evenly to its surface. The powder already absorbs most of the energy.

Laser cladding coating(LMD)

EHLA coating(EHLA)

High Quality and Adaptability

![]() The hardness of the hard stainless steel corrosion-resistant coating reaches HRC50 or above, with no corrosion spots

The hardness of the hard stainless steel corrosion-resistant coating reaches HRC50 or above, with no corrosion spots

![]() The hardness of the superhard wear-resistant coating can reach HRC65 or above, suitable for various types of surface friction and impact wear

The hardness of the superhard wear-resistant coating can reach HRC65 or above, suitable for various types of surface friction and impact wear

![]() Applicable coating thickness of- 0.05-1mm

Applicable coating thickness of- 0.05-1mm

![]() Ra25μm→High surface quality, with a surface roughness of Ra25 μ m after cladding

Ra25μm→High surface quality, with a surface roughness of Ra25 μ m after cladding

![]() Suitable for various material systems such as iron-based, nickel-based, cobalt-based, copper-based, composite materials, etc.

Suitable for various material systems such as iron-based, nickel-based, cobalt-based, copper-based, composite materials, etc.

EHLA – Technical Benefits

![]() Cladding line speed 20-200m/min

Cladding line speed 20-200m/min

![]() Deposition efficiency of 0.8-1.2m ²/h (depending on coating thickness)

Deposition efficiency of 0.8-1.2m ²/h (depending on coating thickness)

![]() The highest powder utilization rate can reach over 95%

The highest powder utilization rate can reach over 95%

![]() No further turning is required, and it can be directly grinded or polished

No further turning is required, and it can be directly grinded or polished

![]() Low laser power requirements

Low laser power requirements

![]() Low heat input, minimal impact on substrate, and minimal deformation of parts

Low heat input, minimal impact on substrate, and minimal deformation of parts

![]() Suitable for multi-layer powder materials and multiple substrate cladding

Suitable for multi-layer powder materials and multiple substrate cladding

Technological Background

EHLA,hailed as a competitive alternative to electroplating technology at present

ACunity Tianjin Co. Ltd is the first to introduce EHLA technology into the Chinese market and has carried out technological industrialization upgrades. This initiative continuously improves the process level and enhances the functionality of core components, such as the durability of powder feeding nozzles, feeding accuracy, high powder feeding volume, and powder utilization rate. Building on the original high-precision coaxial powder feeding nozzle, a modification has been made to officially introduce an efficient and highly convergent powder feeding nozzle. This nozzle achieves a feeding efficiency of over 5 kg/hr and a powder utilization rate of up to 95%. Its special modular design significantly reduces usage costs, simplifies the replacement of worn parts, and ensures process repeatability. The nozzle size can also be flexibly adjusted according to the maintenance position. The newly developed ultra-high-speed laser cladding processing head achieves ideal interaction between light and powder in space through a special optical path adjustment system design, making powder melting more stable and energy utilization more efficient.

A Broad Field for Future Research

Valuable benefits for the environment and enormous economic potential

The high melting performance and good coating quality of EHLA have prompted domestic and foreign scientists to research and study this process. Its continuous application in industrial production depends on its unique technical advantages, good environmental benefits, and enormous economic potential. Because thinner layers can be applied much faster, more precisely , and with less heat input, new application areas are opening up, for example, in the coating of brake disks and in the repair of heat-sensitive components such as landing gear parts in aviation.

The most important future research priorities are the development of EHLA for flat and free-form surfaces, the research and development of new build-up deposition materials and further research into this process in combination with additive manufacturing. The aim is to expand the scope of application of EHLA technology in surface treatment, to further optimize coating quality and to accelerate the development of additive 3D manufacturing technology, which will drive the industrial application of 3D printing technology for metals to a large extent in the future.