Coal Industry

Coal machinery working environment is complex and harsh, equipment running time is extended, bear a large load, especially the underground wet environment, all kinds of harmful gases, dust particles and other issues, easy to cause corrosion, wear and tear on machinery and equipment, will significantly shorten the service life of machinery and equipment. The failure of this equipment is mainly in the form of wear, corrosion, and scratches, such as cut-off teeth, scraper conveyor transport slots, gears, shafts, and other parts of the wear and tear, hydraulic support column cylinder, and piston rod corrosion failure. Hydraulic support columns, cylinders, and further details are currently primarily used to prepare and maintain the corrosion-resistant surface layer of electroplating. However, the low bonding strength of the coating is easy to crack; short service life often needs to be transported from the well for disassembly and maintenance, installation workload, long cycle. Nowadays, intelligent technology is gradually promoted in the coal machine industry to realize uncrewed operations underground. The application of high quality and long service life products is an inevitable trend, which puts forward higher requirements on hydraulic support columns' performance and service life. Applying high efficiency, high quality, and low-cost green manufacturing technology can improve market competitiveness and create long-term value growth for enterprises.

EHLA

For the preparation of corrosion-resistant coatings on the surface of piston rods, spigots, middle cylinders, and other shaft parts of hydraulic supports; unique advantages in the surface coating of parts with large aspect ratios due to low heat input and low deformation.

Inner Laser Cladding

Used for the preparation of corrosion-resistant coating on the inner wall surface of the middle cylinder parts, can replace the traditional arc melting copper process, also can be prepared according to the application requirements of stainless steel, copper alloy coating on the inner wall surface to reduce costs, or for the rapid repair of local damaged areas on the inner surface.

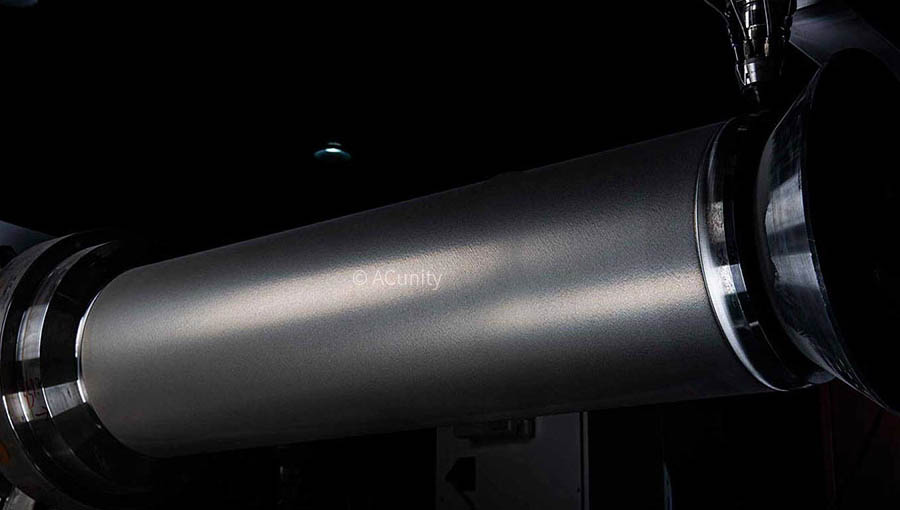

EHLA of Hydraulic Support Column

EHLA can be performed at an ultra-high linear speed of 20-200m/min. Compared with conventional laser cladding technology, it has higher efficiency, lower dilution rate, better coating performance, and lower cost; the extremely high surface finish makes it possible to finish the processing by surface grinding and to polish only in the later process; low heat input and low deformation can be used for coating processing of parts with large aspect ratio. ACUNITY (Tianjin) Co., Ltd. is the first to apply this technology to the scale production of piston rods, live columns, middle cylinders, and other parts in the coal machine industry. The corrosion-resistant coating with a thickness of 0.05-1mm can be prepared quickly at the high efficiency of 0.8-1.2m²/hr (depending on the coating thickness) on the surface of the parts, and the hardness can reach more than HRC50. Mature production line processing specifications have been formed for both new product processing and old product repair.

Laser Cladding of the Inner Wall of the Cylinder

The surface of the cylinder of the hydraulic support column is prone to rusting and forming pits on the inner wall due to the use of unqualified emulsion or long placement time after rising the well. At present, the more common method is to prepare corrosion-resistant coating on the inner surface using arc melting copper technology, which is characterized by high efficiency and large coating thickness, but the heat input is also relatively large and costly. Internal laser cladding technology can somewhat replace or expand the traditional arc-melting copper process for the cladding of smaller-diameter parts. Since the laser cladding method can more easily adjust the powder material, it is convenient to quickly prepare copper alloys, stainless steel, or other coatings with good anti-corrosion properties according to the different service environments and costs. With high integration, good stability, mature process, and wide adaptability, ACUNITY (Tianjin) Co., Ltd.'s inner laser cladding head has been taking the leading position in the field of interior wall radical processing. The minimum inner diameter of the applicable pipe parts is as low as Ф33mm, and the most extended length of one side is up to 3000mm, the highest limit scale range that can be reached by the inner laser cladding and repair technology at domestic and foreign markets. The inner wall of the cylinder is coated with a smooth and defect-free surface, which not only significantly reduces the amount of subsequent processing, but also has almost no thermal deformation effect on the product, no need to reserve machining allowances, and greater freedom in the arrangement of the production process of the product.