Material Design for the High Quality Coating

We have systematically studied special physical processes such as high-temperature powder melting and high-speed cooling of the melt pool during EHLA process for customers in different industrial fields. We have scientifically selected powder materials and prepared different types of high-quality functional coatings, with significant advantages such as high density,defect-free, high bonding strength, and low dilution rate. Coating materials include various types,such as iron-based, nickel-based, titanium-based, copper-based, cobalt-based, tin-based, and metal-based composite materials.

Characteristics of EHLA Coating

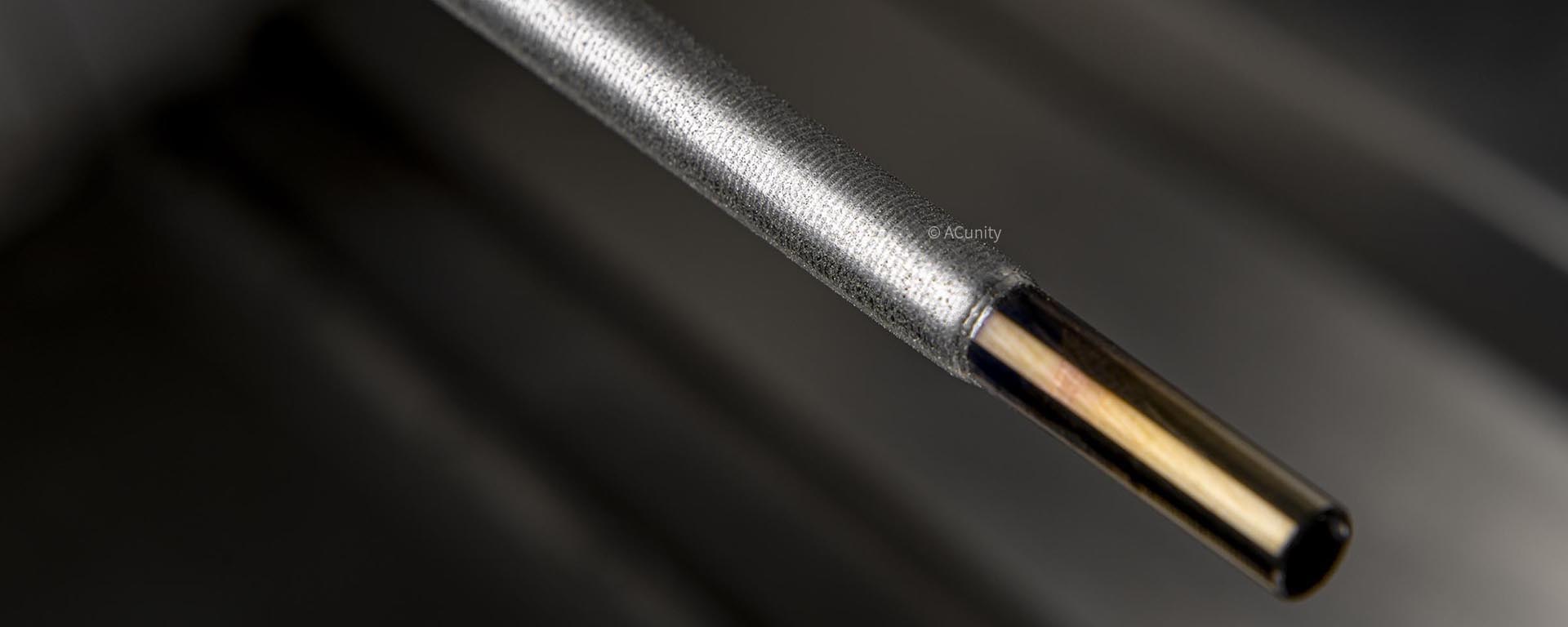

Unlike traditional laser cladding methods that operate at lower speeds, Extreme High-Speed Laser Metal Deposition (EHLA) performs laser cladding at high speeds, where most of the powder is melted in space. The laser forms a shallower, smaller melt pool on the substrate material, resulting in ultra-fast cooling rates. As the cladding rate increases, the overlap rate between cladding tracks gradually rises, allowing for the formation of a "domino" like multi-thin layer overlapping structure. This imparts a more uniform microstructure to the coating, minimizes residual stress, and reduces thermal impact on the substrate. The unique melting and solidification characteristics of the metal powder used in ultra-high-speed laser cladding can even produce some coating materials that are difficult to achieve with traditional laser cladding, such as intermetallic compounds, amorphous materials, metallic glasses, and high-content metal composites.

拷贝-14180612303.jpg)

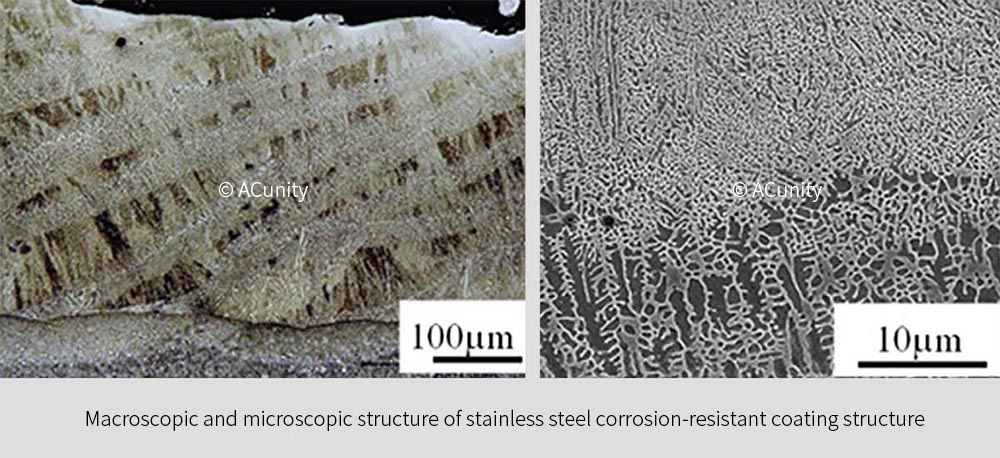

Corrosion Resistant Coating

To achieve good corrosion resistance, coating materials often select stainless steel powders with high Cr content or nickel- based powders.

Under conditions of high-speed laser cladding, dendritic structures as small as 700 nm can be formed in stainless steel coatings. As the cladding rate increases, the dendrites become more refined and the element distribution more uniform. Corrosion tests indicate that the faster the cladding rate, the better the corrosion resistance of the coating. This is because many dislocations and stacking faults are found in the coatings prepared at higher laser cladding rates, which are highly conducive to the nucleation of passive films. A dense passive film forms on the surface of the coating, enhancing its corrosion protection capabilities.

Research has found that pitting corrosion of coatings often occurs at the junction between dendrites, as the Cr content here decreases. High melting rates refine the dendrites of the coating, resulting in a uniform distribution of components, which is more conducive to improving the corrosion resistance of the coating.

Hard Wear-Resistant Coating

Wear resistant coatings can be prepared using the following types of powders.

![]() Hard alloy powder

Hard alloy powder

![]() Adding composite material powders with reinforcing phases, such as nickel-based WC powder.

Adding composite material powders with reinforcing phases, such as nickel-based WC powder.

![]() Metal powders that can generate reinforcement phases in situ, such as iron-based and titanium-based powders that can generate VC and TiC reinforcement phases in situ.

Metal powders that can generate reinforcement phases in situ, such as iron-based and titanium-based powders that can generate VC and TiC reinforcement phases in situ.

Hard wear-resistant coatings are prone to crack formation during laser cladding, therefore crack control is a key point in the preparation of such coatings. Some industrial applications have high requirements for the uniformity of surface hardness of coatings, so more attention is paid to the uniform distribution control of hard reinforcement phases on the coating surface.

When preparing wear-resistant coatings for metal composite materials, EHLA process has a small melt pool and a superimposed coating structure, which makes it easier to achieve uniformity control of the reinforcement phase and microstructure of the coating. The melt pool has a rapid cooling rate and a short high-temperature residence time, greatly reducing the reaction time between the reinforcement particles and the alloy metal, and can reduce the tendency for cracks.

拷贝-10072423515.jpg)

For in-situ reinforced hard coatings, the high cooling rate of the melt pool during the EHLA process is very conducive to the full precipitation of the reinforcing phase and the acquisition of a uniform and dense microstructure. Under the action of fine grain strengthening and second phase strengthening, the coating hardness and uniformity of hardness are significantly higher than those of conventional laser cladding coatings. By controlling the cooling rate, enhanced phase morphology of different structures can also be obtained.