Deep interpretation! The current application status of laser cladding in marine equipment materials

2023-08-03The 21st century belongs to the century of the ocean. In world trade, over 90% of freight relies on ocean transportation; The world's newly added oil and gas reserves and production mainly come from the ocean; Therefore, marine resources and the maritime industry have become indispensable pillars in the development of the world economy. However, the corrosion of metal materials by marine organisms and their metabolites has made the marine environment an extremely harsh corrosive environment. Whether it is ships on the sea surface or underwater oil extraction wellheads, high-strength and corrosion-resistant materials need to be used for manufacturing, and anti-corrosion coatings need to be applied for protection. Therefore, the development of high-performance marine oil equipment materials has important strategic significance for the efficient development and utilization of marine oil.

Characteristics of seawater corrosion

1. Seawater is a typical electrolyte solution that undergoes electrochemical corrosion on metals. The anodic polarization inhibition of seawater corrosion is minimal for most metals such as iron, steel, cast iron, zinc, cadmium, etc., resulting in a relatively fast corrosion rate. Only a very small number of easily passivated metals, such as titanium, zirconium, tantalum, niobium, etc., can maintain their passivation state in seawater and have a significant anodic blocking effect.

2. Except for magnesium and its alloys, the corrosion of the vast majority of marine structural materials in seawater is controlled by the cathodic process of oxygen depolarization. All favorable conditions for oxygen supply, such as waves, splashes, and increased flow velocity, will promote the cathodic depolarization reaction of oxygen and promote the corrosion of steel.

3. Small hole corrosion is prone to occur in seawater, and the hole depth is also relatively deep.

The current mainstream anti-corrosion processes include solvent based paint, electroplating thermal spraying, acid phosphating, traditional sandblasting rust removal, etc. The most common method is to spray/line, plate, or coat a layer of metal or non-metal material with good corrosion resistance on the metal surface. To achieve excellent anti-corrosion effect, it is necessary to meet the requirements of tight structure, complete and pore free, impermeable to media, good adhesion with basic metals, high hardness, high wear resistance, and uniform distribution.

However, traditional electroplating and spray coating have poor adhesion, are prone to cracking and peeling, and have a short service life. Marine equipment is in a complex and ever-changing marine environment, and installation and maintenance are not only expensive, but also difficult to operate. Therefore, during the construction and service period of marine equipment materials, it is necessary to fully consider and evaluate the effects of various loads acting alone or in combination, to ensure that the materials meet the service requirements.

Laser cladding materials mainly include nickel based, iron-based, cobalt based, copper based self melting alloys, as well as metal ceramic composite powders composed of the above alloys and carbide (WC, TiC, SiC, etc.) particles, and ceramic materials such as AI203 and Zr02. Applicable workpiece substrates include steel, aluminum alloys, copper alloys, nickel alloys, and titanium alloys.

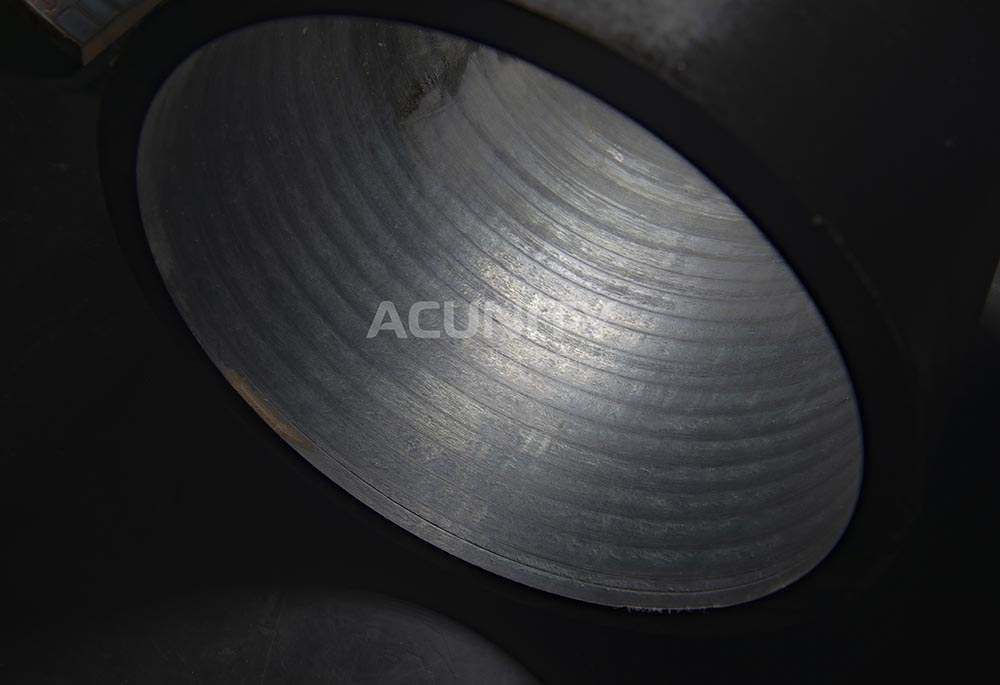

The use of laser cladding technology for repairing and rebuilding marine machinery involves metallurgical bonding between the laser cladding layer and the substrate. At the same time, the cladding material can be well selected to fill large defects such as grooves, pits, and holes, which cannot be compared to traditional repair processes such as brushing, spraying, and coating.

In the application of marine machinery in China, iron-based metal materials dominate, and at the same time, the failure of metal materials (such as corrosion, wear, fatigue, etc.) mostly occurs on the working surface of components, requiring surface strengthening. Using large and expensive metal materials to meet the service conditions of the workpiece not only wastes materials, but also incurs high costs. The use of laser cladding technology to fuse expensive non-ferrous metal materials onto iron-based components can result in lighter weight and higher hardness. Good wear resistance. Corrosion resistance. High temperature resistance. Components with comprehensive properties such as anti-oxidation can effectively solve the maintenance work of marine machinery.